Bauxite consists of aluminium oxide (Alumina), silica, iron oxides, and titanium dioxide. Approximately 70 per cent of the world's bauxite production is refined through the Bayer chemical process to produce Alumina. Alumina is then further processed into pure aluminium metal using the Hall–Héroult electrolytic process.

Australia, China, Brazil, India, and Guinea are the leading countries that produce Bauxite. In the Gulf Cooperation Council (GCC), the Kingdom of Saudi Arabia is the only country with bauxite mines. The United Arab Emirates imports bauxite from overseas for its alumina refinery in Al Taweelah.

When extracted from Bauxite, Alumina typically appears as a white powder that resembles table salt or granular sugar. The Bayer process converts Bauxite into Alumina. Approximately two tons of Bauxite are required to produce one ton of Alumina.

The Bayer Process

Bauxite undergoes processes starting with crushing, washing, and drying. Next, it is dissolved in caustic soda at high temperatures.

The resulting mixture is then filtered to eliminate impurities, known as "red mud," which are disposed of properly. The remaining alumina solution is transferred to tanks called precipitators, where aluminium hydroxide seeds are added. These seeds promote the precipitation of solid aluminium hydroxide crystals. As the crystals form, the aluminium hydroxide settles at the bottom of the tank and is subsequently removed.

Afterwards, the aluminium hydroxide is washed to remove any remaining caustic soda and heated to eliminate excess water. This process produces Alumina (aluminium oxide) as a fine white powder.

Aluminium oxide is the main raw material in primary aluminium production and has several industrial applications. It is commonly used as a plastic filler and a popular abrasive, serving as a cost-effective alternative to industrial diamonds. Additionally, aluminium oxide flakes create reflective effects in automotive paint.

In the Hall–Héroult process, Alumina is dissolved in a molten cryolite bath within a carbon-lined steel pot. Carbon anodes are inserted at the top of the bath, and an electric current passes through the anodes and the bath. Oxygen atoms separate from the Alumina and combine with the carbon anode, leaving the remaining molten Aluminium at the bottom of the pot. The molten Aluminium is periodically siphoned out and placed in a holding furnace. From the holding furnace, the molten Aluminium is cast into an ingot.

Aluminium production is energy-intensive, and no viable alternatives exist to the Hall–Héroult process.

After the extrusion process, the materials typically undergo various fabrication and finishing processes to be transformed into usable components in commercial and residential buildings for applications such as window and door frames, prefabricated structures, roofing, exterior cladding, curtain walls, and shop fronts. Additionally, extrusions are crucial in the mass transportation industry, utilised in airframes, road and rail vehicles, and marine applications.

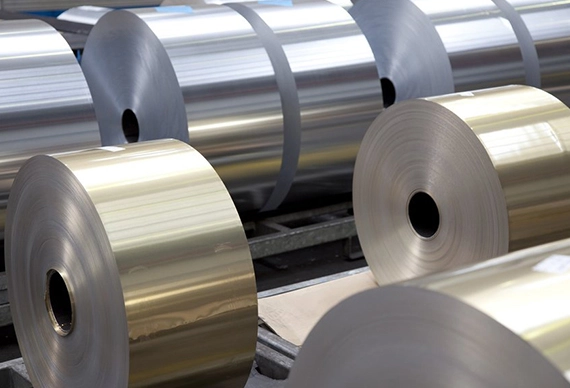

This process changes the metal's characteristics, making it less brittle and more ductile. Rolled aluminium products are commonly used in various applications, including home appliances, packaging, transportation, construction, and many others.

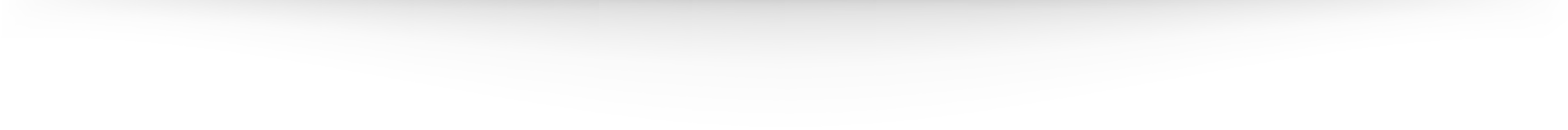

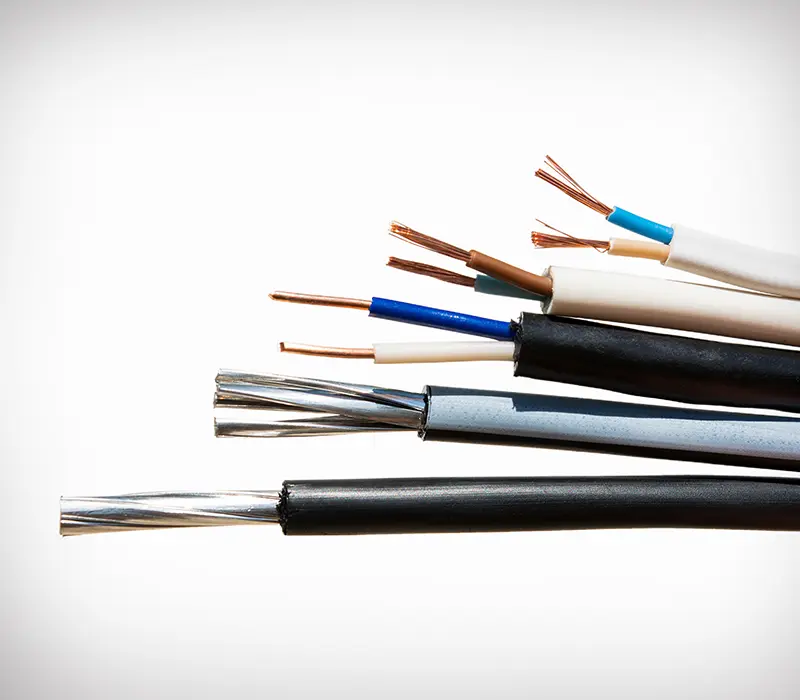

Aluminium rods and bars are produced through various processes, including extrusion, rolling, coiling, and drawing from molten Aluminium. These processes elongate the Aluminium into circular or bar-shaped pieces that can be machined for different applications. Many machine parts, such as rivets, nails, screws, and bolts, are made from aluminium rods and bars. Additionally, aluminium wire is commonly used in electrical transmission applications because of its superior conductivity and resistance to corrosion.

Aluminium rods, bars, and wire production begins by heating a long square ingot. This ingot is then progressively reduced in cross-section by passing it through a series of rolls. The resulting material is coiled, and if intended to become wire, it is pulled through increasingly smaller dies. Electrical conductors are created by stranding several cables together into a single piece.

There are three main types of forging processes:

1. Open-die forging: Ideal for larger aluminium components.

2. Closed-die forging: Suitable for more intricate designs and tighter tolerances.

3. Ring-rolled forging: Used to create high-strength, ring-shaped products.

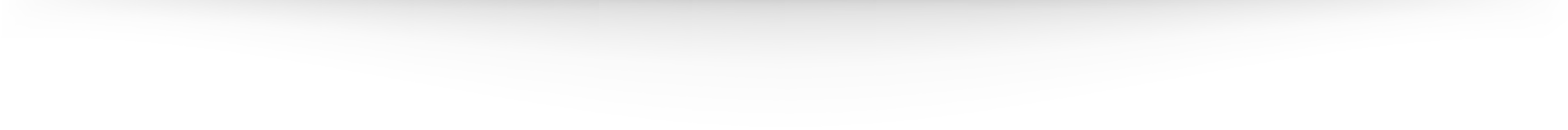

In this process, molten Aluminium is poured into a mould to create the desired shape. The three primary casting methods are die casting, permanent mould, and sand casting. The automotive industry is the largest market for aluminium casting, with cast products accounting for over half of the Aluminium used in cars.

This process creates droplets of various sizes. These aluminium products are used in multiple applications, including explosives, rocket fuel, metallurgy, chemicals, links, and solar cells.

Its density is only one-third that of steel.

to weather, common atmospheric gases and a wide range of liquids.

and as a result, is employed in several decorative applications.

formed easily shaped by any of the main industrial metal working processes - rolling, extrusion

It can strengthen steel by only one-third of its weight if mixed with other alloys.

it is ideal for food and drink packaging and containers. It keeps out air, light, and microorganisms while preserving the contents.

Aluminium can be recycled repeatedly, using only 5% of the energy required to create “new” metal.

Ideal for long-lasting, sturdy structures.

which is an advantage in structures under shock loads.

Conducts electricity and heat nearly as well as copper.

It is invaluable in advanced industries such as electronics or offshore structures.

The third most abundant element in the Earth’s crust.